Company Profile

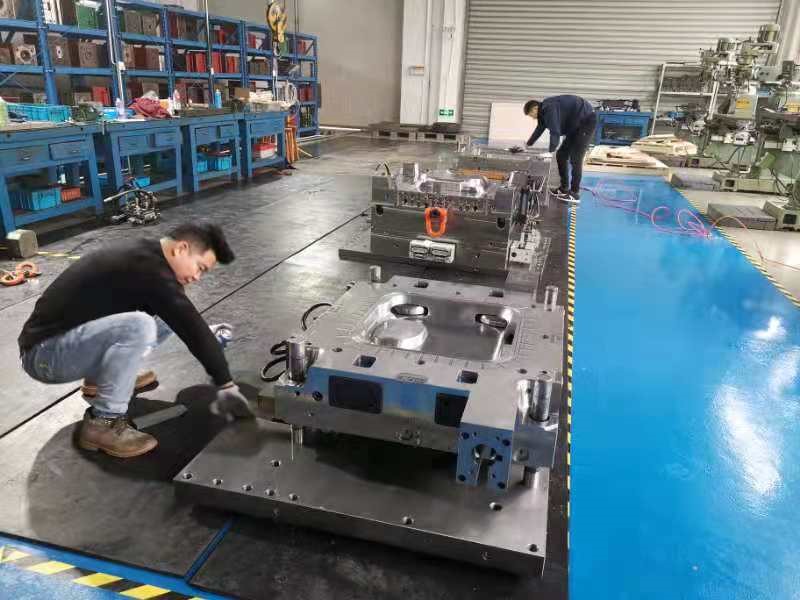

Shanghai Jinyili Molding Technology Co., Ltd. specialized in plastic mold design, processing, manufacturing and sales, as well as injection molding production of plastic products. We mainly serve many high value-added industries such as electronic industry, telecommunication, automobile, medical treatment, food packaging, etc. From parts design to mold making to injection production, we provide the most advanced manufacturing technology and professional consultation for various projects. Our molds are shipped to the United States, Japan and Europe to support our customers.

NowOur current fixed assets have reached 50 million RMB. Our factory covers an area of 5000 square meters with dust-free workshops and has more than 50 skilled employees,3 project managers ,3 engineers,software we usually use is UG and PROE. We also have ISO & TS16949 certificates.We are committed to providing high- quality products with high cost performance for customers at home and abroad.

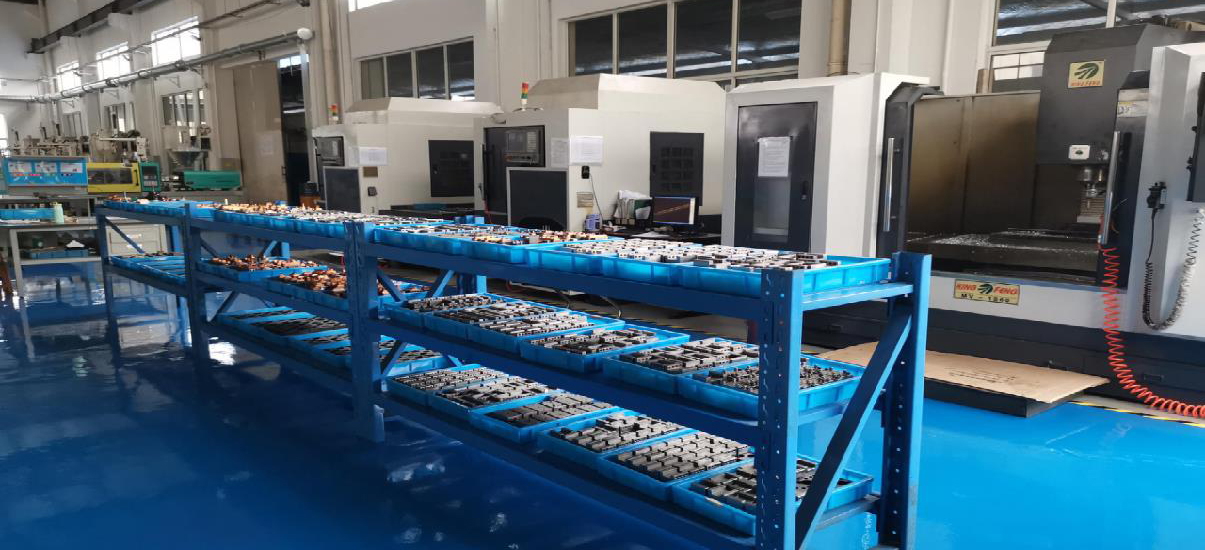

Equipment list of mould workshop

| Machine name | Quantity of equipment |

| CNC | 4 sets |

| Milling machine | 4 sets |

| Spark machine | 5 sets |

| Drilling machine | 2 sets |

| Grinding machine | 3 sets |

| Lathe | 2 sets |

| Radial drilling machine | 3 sets |

Usual used Mold steel type

| STANDARDS | Ref. HARDNESS | ||||

| UDDEHOLM | ASSAB | W.nr | AISI | JIS | |

| RIGOR | XW-10 | 1.2363 | A2 | SKD12 | HRC59-61 |

| CALMAX | 635 | S7 | HRC55-57 | ||

| ASSAB 618 | ASSAB618 | 1.2738 | P20 | HRC38-41 | |

| RAMAXS | 168 | 1.2083 | 420 | SUS420 | HRC32-36 |

| ORVAR SUPREME | 8407 | 1.2344 | H13 | SKD61 | HRC51-53 |

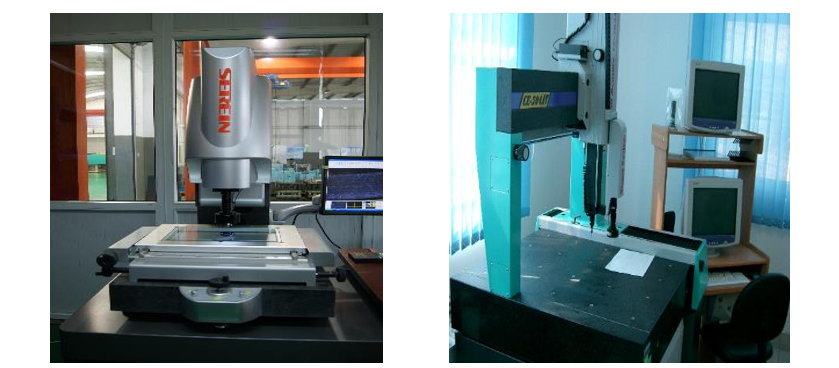

Inspection equipment

Company's mission: let our customer success

Company vision: to become a professional supplier for precision plastic part

Company’s core value: pragmatic cooperation

Workshop show