Injection Molding

-

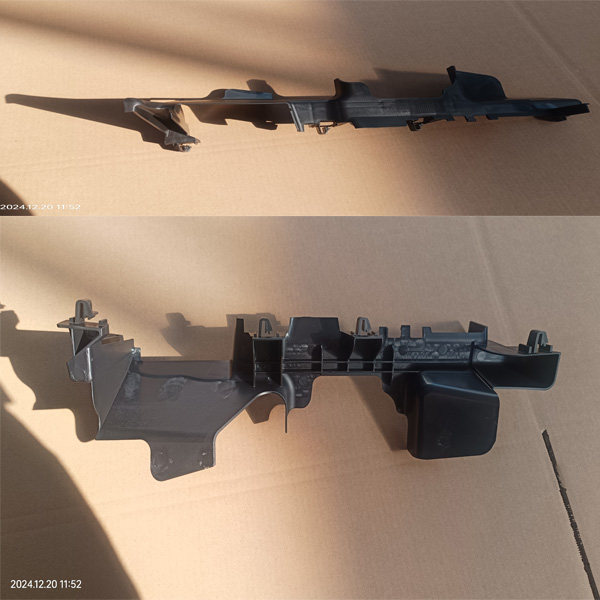

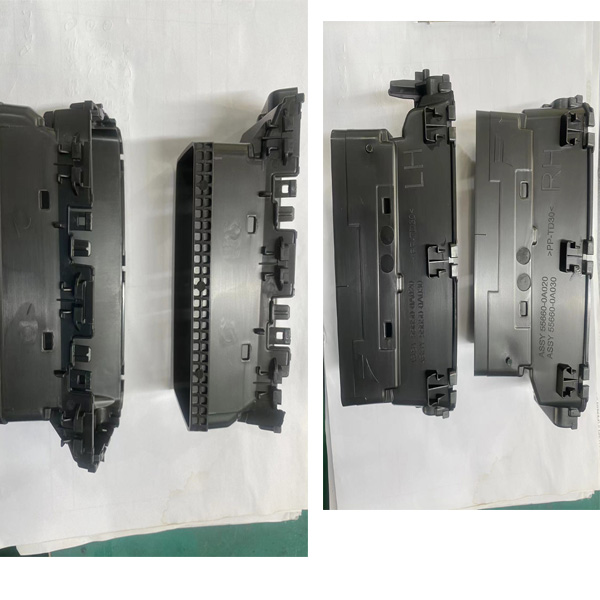

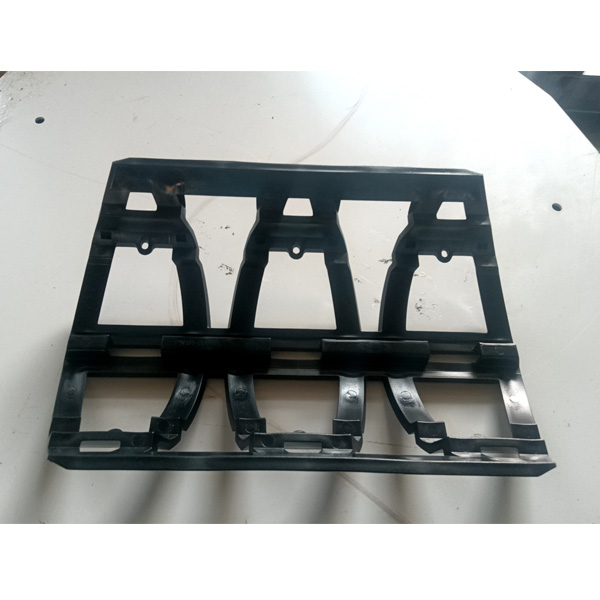

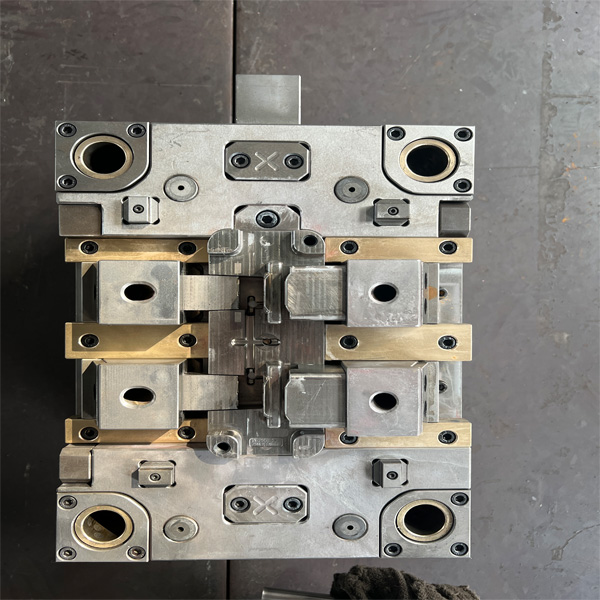

Plastic injection mold for automobile air guide Plastic Injection Mould Plastic Injection Mould Make Mold Maker

Plastic injection mold for automobile air guide Plastic Injection Mould Plastic Injection Mould Make Mold Maker Product:china oem plastic injected part mold

Molde de injeção de plástico para ar automotivo GUI injeção plástica MevenLD injeção plástica MevenLD fabricante de moldes

Molde de inyección de plástico para aire de automóvil GUI inyección de plástico MevenLD inyección de plástico MevenLD hacer fabricante de moldes

Moule d’injection plastique pour automobile air GUI injection plastique MevenLD injection plastique MevenLD faire fabricant de moules

stampo a iniezione di plastica per aria per automobili GUI iniezione di plastica MevenLD iniezione di plastica MevenLD realizza stampi

Design software:PROE.UG.CADMachine:CNCShaping Mode:Plastic Injection MouldBrand Name:china oem plastic injected part moldDesign Software:UG,PRO,CADProduct Material:plasticCertificate:ISO9001Brand Name:OEMModel Number:plastic injection mould-Product Material:SteelProduct:Industrial moldRunner:Cold /HotCavity:Single/MultiAdvantage:Reasonable price,high quality,on timeDelivery time:28-30daysPayment:L/C TT Western UnionPackaging:Wooden cartonsSoftware de design: PROE.UG.CAD

Máquina: CNC

Modo de moldagem: molde de injeção de plástico

Marca: molde de peça injetada de plástico OEM da China

Software de design: UG, PRO, CAD

Material do produto: plástico

Certificado: ISO9001

Marca: OEM

Número do modelo: molde de injeção de plástico-

Material do produto: Aço

Produto: Molde industrial

Corredor: Frio/Quente

Cavidade: Única/Múltipla

Vantagem: preço razoável, alta qualidade, pontualidade. Prazo de entrega: 28 a 30 dias.

Pagamento: L/C TT Western Union

Embalagem: Caixas de madeiraSoftware di progettazione: PROE.UG.CAD

Macchina: CNC

Modalità di formatura: stampo a iniezione di plastica

Marchio: stampo per iniezione di parti in plastica OEM cinese

Software di progettazione: UG, PRO, CAD

Materiale del prodotto: plastica

Certificato: ISO9001

Nome del marchio: OEM

Numero di modello: stampo per iniezione di plastica

Materiale del prodotto: acciaio

Prodotto:Stampo industriale

Corridore: Freddo / Caldo

Cavità: singola/multipla

Vantaggio: prezzo ragionevole, alta qualità, consegna puntuale. Tempi di consegna: 28-30 giorni.

Pagamento: L/C TT Western Union

Imballaggio: Scatole di legnoLogiciel de conception : PROE.UG.CAD

Machine : CNC

Mode de mise en forme : moule d’injection plastique

Nom de marque : moule de pièce injectée en plastique OEM de Chine

Logiciels de conception : UG, PRO, CAD

Matériau du produit : plastique

Certificat : ISO9001

Nom de marque : OEM

Numéro de modèle : moule d’injection plastique-

Matériau du produit : acier

Produit : Moule industriel

Coureur : Froid / Chaud

Cavité : simple/multiple

Avantage : prix raisonnable, haute qualité, délai de livraison : 28-30 jours

Paiement : L/C TT Western Union

Emballage : Cartons en boisSoftware di progettazione: PROE.UG.CAD

Macchina: CNC

Modalità di formatura: stampo a iniezione di plastica

Marchio: stampo per iniezione di parti in plastica OEM cinese

Software di progettazione: UG, PRO, CAD

Materiale del prodotto: plastica

Certificato: ISO9001

Nome del marchio: OEM

Numero di modello: stampo per iniezione di plastica

Materiale del prodotto: acciaio

Prodotto:Stampo industriale

Corridore: Freddo / Caldo

Cavità: singola/multipla

Vantaggio: prezzo ragionevole, alta qualità, consegna puntuale. Tempi di consegna: 28-30 giorni.

Pagamento: L/C TT Western Union

Imballaggio: Scatole di legnoapplication:

electrotechnics,electronics,automotive,household goods,precision mechanics,medical technologyinjeção de plásticocertas aplicações LD:

eletrotécnica, eletrónica, automóvel, utensílios domésticos, mecânica de precisão, tecnologia médica

iniezione di plastica, alcune applicazioni LD:

elettrotecnica, elettronica, automotive, articoli per la casa, meccanica di precisione, tecnologia medica

injection plastiquecertaines applications LD :

électrotechnique, électronique, automobile, articles ménagers, mécanique de précision, technologie médicale

Inyección de plástico, ciertas aplicaciones de LD:

electrotécnica, electrónica, automoción, artículos para el hogar, mecánica de precisión, tecnología médica

-

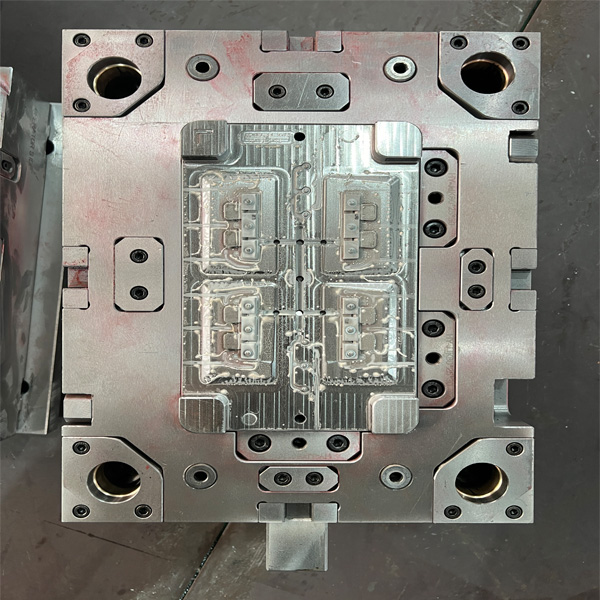

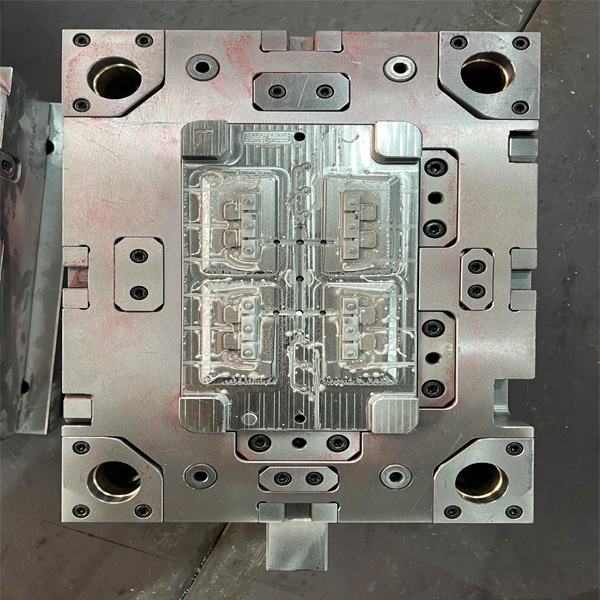

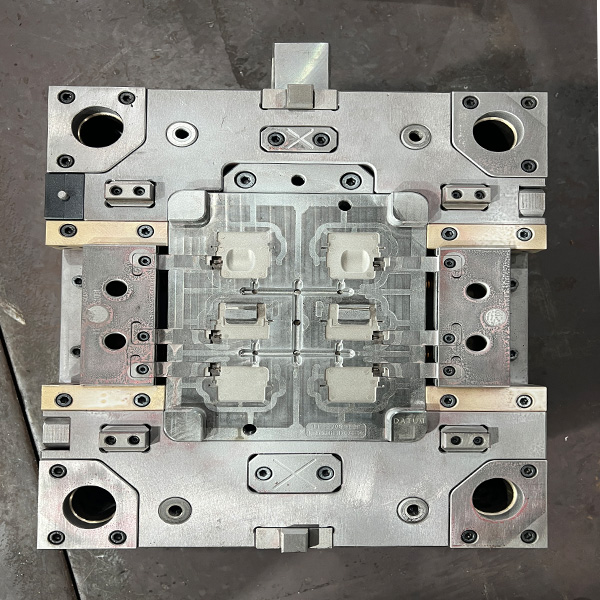

Automobile wiring duct Plastic Injection Mould Plastic Injection Mould Make Mold Maker

Automobile wiring duct Plastic Injection Mould Plastic Injection Mould Make Mold Maker

Product:china oem plastic injected part moldDesign software:PROE.UG.CADMachine:CNCShaping Mode:Plastic Injection MouldBrand Name:china oem plastic injected part moldDesign Software:UG,PRO,CADProduct Material:plasticCertificate:ISO9001Brand Name:OEMModel Number:plastic injection mould-Product Material:SteelProduct:Industrial moldRunner:Cold /HotCavity:Single/MultiDelivery time:28-30daysPayment:L/C TT Western UnionPackaging:Wooden cartons -

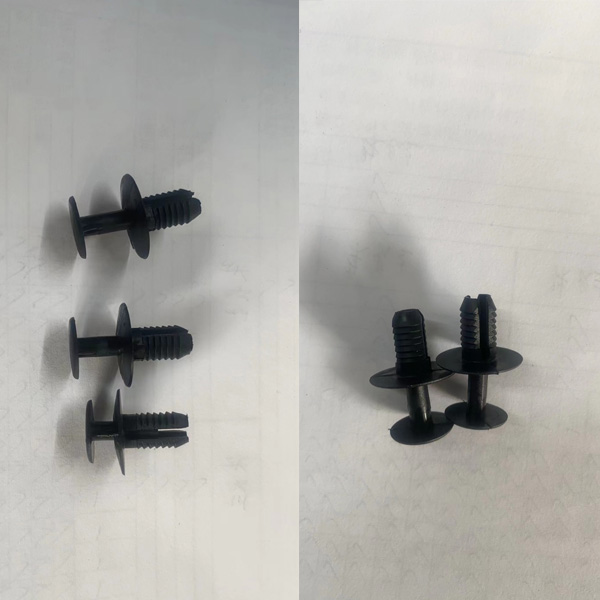

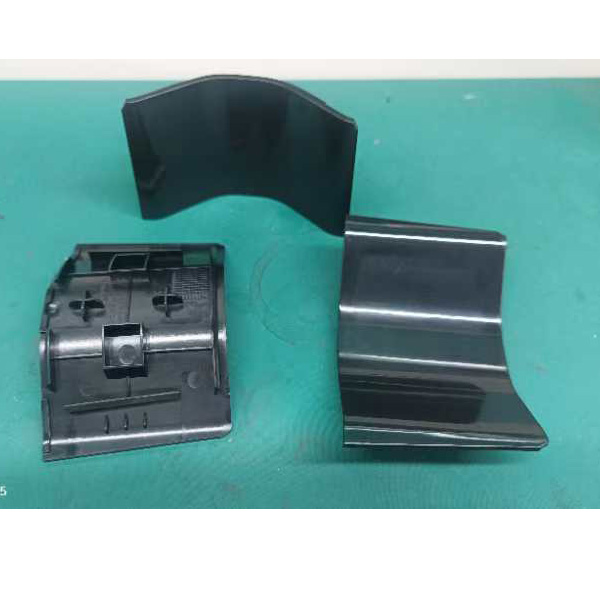

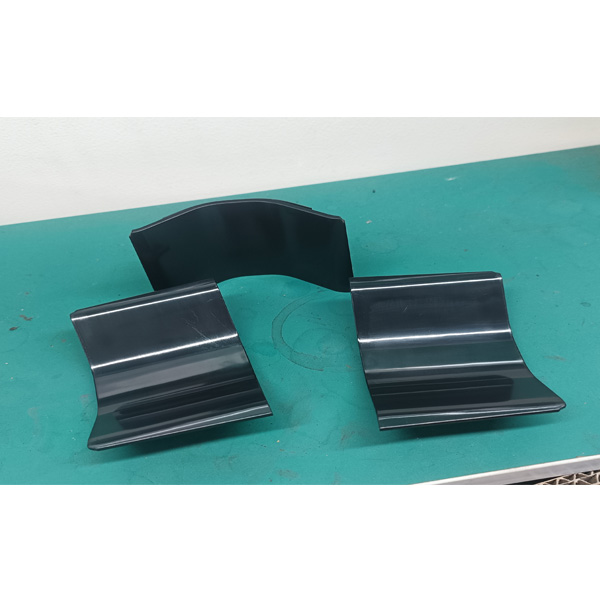

Car small bucklePlastic Injection Mould Plastic Injection Mould Make Mold Maker

Car small bucklePlastic Injection Mould Plastic Injection Mould Make Mold Maker

Product:china oem plastic injected part moldDesign software:PROE.UG.CADMachine:CNCShaping Mode:Plastic Injection MouldBrand Name:china oem plastic injected part moldDesign Software:UG,PRO,CADProduct Material:plasticCertificate:ISO9001Brand Name:OEMModel Number:plastic injection mould-Product Material:SteelProduct:Industrial moldRunner:Cold /HotCavity:Single/MultiAdvantage:Reasonable price,high quality,on timeDelivery time:28-30daysPayment:L/C TT Western Union -

Kettle lid Plastic Injection Mould Plastic Injection Mould Make Mold Maker With High Quality Cheap Price

Kettle lid Plastic Injection Mould Plastic Injection Mould Make Mold Maker With High Quality Cheap Price

Product:china oem plastic injected part moldDesign software:PROE.UG.CADMachine:CNCShaping Mode:Plastic Injection MouldBrand Name:china oem plastic injected part moldDesign Software:UG,PRO,CADProduct Material:plasticCertificate:ISO9001Brand Name:OEMModel Number:plastic injection mould-Product Material:SteelProduct:Industrial moldRunner:Cold /HotCavity:Single/MultiAdvantage:Reasonable price,high quality,on timeDelivery time:28-30daysPayment:L/C TT Western Union -

Auto Parts Plastic Injection Mould Plastic Injection Mould Make Mold Maker factory

Auto Parts Plastic Injection Mould Plastic Injection Mould Make Mold Maker With High Quality

Place of Origin:Shanghai China(Mainland)Product:china oem plastic injected part moldDesign software:PROE.UG.CADMachine:CNCShaping Mode:Plastic Injection MouldBrand Name:china oem plastic injected part moldDesign Software:UG,PRO,CADProduct Material:plasticCertificate:ISO9001Brand Name:OEMModel Number:plastic injection mould-Product Material:SteelProduct:Industrial moldRunner:Cold /HotCavity:Single/MultiAdvantage:Reasonable price,high quality,on timeDelivery time:28-30daysPayment:L/C TT Western Union -

Auto Parts Plastic Injection Mould Plastic Injection Mould Make Mold Maker With High Quality Cheap Price

Auto Parts Plastic Injection Mould Plastic Injection Mould Make Mold Maker With High Quality

Place of Origin:Shanghai China(Mainland)Product:china oem plastic injected part moldDesign software:PROE.UG.CADMachine:CNCShaping Mode:Plastic Injection MouldBrand Name:china oem plastic injected part moldDesign Software:UG,PRO,CADProduct Material:plasticCertificate:ISO9001Brand Name:OEMModel Number:plastic injection mould-Product Material:SteelProduct:Industrial moldRunner:Cold /HotCavity:Single/MultiAdvantage:Reasonable price,high quality,on timeDelivery time:28-30daysPayment:L/C TT Western Union -

Cup Holder Plastic Injection Mould Plastic Injection Mould Make Mold Maker With High Quality Cheap Price

Cup Holder Plastic Injection Mould Plastic Injection Mould Make Mold Maker With High Quality

Cheap Price

Place of Origin:Shanghai China(Mainland)Product:china oem plastic injected part moldDesign software:PROE.UG.CADMachine:CNCShaping Mode:Plastic Injection MouldBrand Name:china oem plastic injected part moldDesign Software:UG,PRO,CADProduct Material:plasticCertificate:ISO9001Brand Name:OEMModel Number:plastic injection mould-Product Material:SteelProduct:Industrial moldRunner:Cold /HotCavity:Single/MultiAdvantage:Reasonable price,high quality,on timeDelivery time:28-30daysPayment:L/C TT Western Union -

Professional OEM/ODM Design One-Stop Service Plastic Injection Mold Processing

Professional OEM/ODM Design One-Stop Service Plastic Injection Mold Processing

Place of Origin:Shanghai China(Mainland)Product:china oem plastic injected part moldDesign software:PROE.UG.CADMachine:CNCShaping Mode:Plastic Injection MouldBrand Name:china oem plastic injected part moldDesign Software:UG,PRO,CADProduct Material:plasticCertificate:ISO9001Brand Name:OEMModel Number:plastic injection mould-Product Material:SteelProduct:Industrial moldRunner:Cold /HotCavity:Single/MultiAdvantage:Reasonable price,high quality,on timeDelivery time:28-30daysPayment:L/C TT Western Union -

high precision mould maker plastic parts inject molding service moulding abs plastic injection mold

high precision mould maker plastic parts inject molding service moulding abs plastic injection moldProduct:auto parts Product

Place of Origin:Shanghai China(Mainland)Product:china oem plastic injected part moldDesign software:PROE.UG.CADMachine:CNCShaping Mode:Plastic Injection MouldBrand Name:china oem plastic injected part moldDesign Software:UG,PRO,CADProduct Material:plasticCertificate:ISO9001Brand Name:OEMModel Number:plastic injection mould-Product Material:SteelProduct:Industrial moldRunner:Cold /HotCavity:Single/MultiAdvantage:Reasonable price,high quality,on timeDelivery time:28-30daysPayment:L/C TT Western Union -

Manufacturer custom made screw cap plastic injection moulding/Plastic Injection Molds/Plastic Injection Molding for industry

Automobile parts Plastic injection Moulds/mold/die of auto part/car accessory

Product:auto parts ProductPlace of Origin:Shanghai China(Mainland)Product:china oem plastic injected part moldDesign software:PROE.UG.CADMachine:CNCShaping Mode:Plastic Injection MouldBrand Name:china oem plastic injected part moldDesign Software:UG,PRO,CADProduct Material:plasticCertificate:ISO9001Brand Name:OEMModel Number:plastic injection mould-Product Material:SteelProduct:Industrial moldRunner:Cold /HotCavity:Single/MultiAdvantage:Reasonable price,high quality,on timeDelivery time:28-30daysPayment:L/C TT Western Union -

Customized equipment tools plastic injection mould for Audi auto parts

Automobile parts Plastic injection Moulds/mold/die of auto part/car accessory

Product:auto parts ProductPlace of Origin:Shanghai China(Mainland)Product:china oem plastic injected part moldDesign software:PROE.UG.CADMachine:CNCShaping Mode:Plastic Injection MouldBrand Name:china oem plastic injected part moldDesign Software:UG,PRO,CADProduct Material:plasticCertificate:ISO9001Brand Name:OEMModel Number:plastic injection mould-Product Material:SteelProduct:Industrial moldRunner:Cold /HotCavity:Single/MultiAdvantage:Reasonable price,high quality,on timeDelivery time:28-30daysPayment:L/C TT Western Union -

plastic disposable mould PP plastic meal house hold compartment disposable home appliance

plastic disposable mould PP plastic meal house hold compartment disposable home appliancePlace of Origin:Shanghai, China

Brand Name:OEMModel Number:household injection mouldProduct Material:SteelProduct:Industrial moldProduct Name:Industrial moldDesign Software:UG ,Proe ,CAD/CAM,ectMaterial:SteelRunner:Cold /HotCavity:Single/MultiAdvantage:Reasonable price,high quality,on timeDelivery time:28-30daysPayment:L/C TT Western Union D/PPackaging:Wooden cartons