With the development of injection mold industry, equipment update of mold processing technology, the wide application of various new mold materials, the standardization and specialization of mold parts, etc., all force us to design faster and better adapt to the development of molds.

The improvement of speed requires that the design section can be completed in about 3 days; the improvement of precision requires that the processing method of each part be considered clearly during the design process, and the processing method with high precision and low processing cost should be adopted as much as possible.

Accuracy and speed improvements go hand in hand. The improvement of speed will inevitably require the improvement of precision; the improvement of precision will inevitably lead to the improvement of speed.

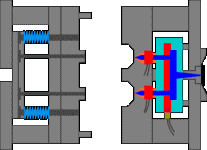

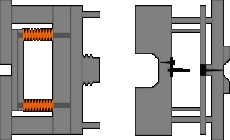

Hot runner system

The inner barb mechanism of the inclined roof

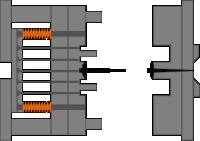

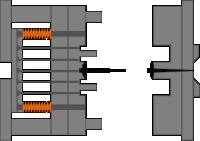

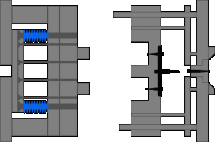

Sleeve ejection mechanism

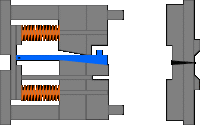

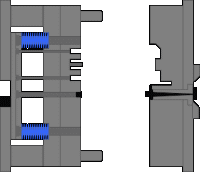

Outer barb mechanism of slider

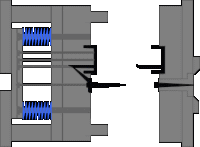

Internal thread automatic unscrewing and demoulding mechanism

Three-plate mold, needle point glue feeding, sleeve ejection mechanism

Side wall latent glue feeding mechanism

Embedded part injection mechanism

Ejector latent glue feeding mechanism

Hub barb mechanism

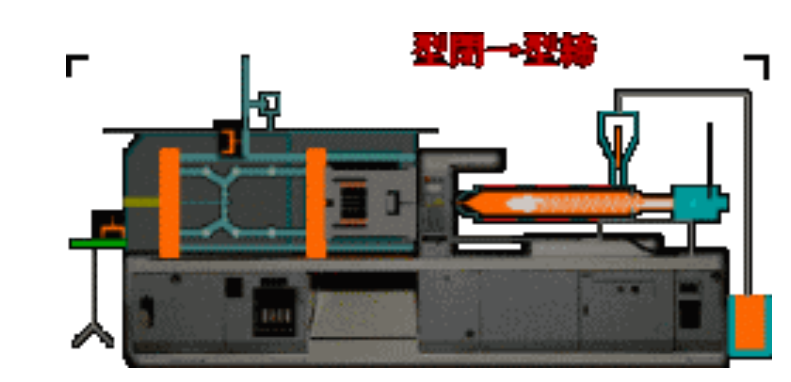

Injection molding machine

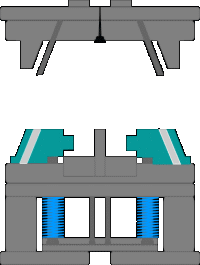

Basic structure of plastic mold

According to the overall functional structure, plastic molds can be divided into: guiding system, supporting system, forming parts system, pouring system, cooling system, ejection system, and exhaust system.

Definition: The plastic flow channel in the mold from the nozzle of the injection machine to the cavity. It consists of main channel, runner, gate and cavity.

Some relevant Chinese and English comparisons

CAV.NO No. mold nest RUNNER sprue

GATE gate CAVITY cavity

What expertise is required for structural design

, personal opinion, for reference only! If there is a mistake, please leave a message to correct me, thank you!

Post time: May-10-2023